Baked enamel and powder coat are both durable coating options, with baked enamel being applied as a liquid and then baked, while powder coat is applied as a dry powder and then cured with heat.

When it comes to enhancing the durability and appearance of various products, it is essential to understand the differences between two popular finishing methods: baked enamel and powder coat. Both techniques offer their own unique advantages and considerations. In this article, we will delve into the intricacies of baked enamel and powder coat, helping you make an informed decision for your specific needs.

Now, Need to know!

What Is Baked Enamel?

Baked enamel, also known as wet spray enamel, is a traditional finishing process that involves applying a liquid coating onto a substrate or product. The coated item is then heated in a specialized oven, allowing the enamel to cure and form a hard, durable finish. This curing process gives baked enamel its name, as it involves baking the coating to achieve optimal adhesion and strength.

What Is Powder Coat?

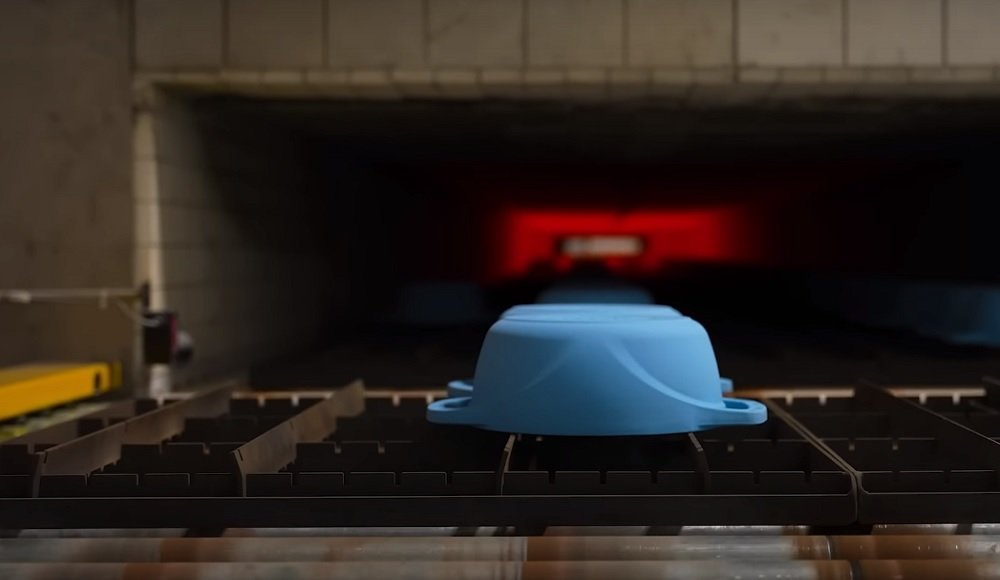

Powder coat is a more modern finishing technique that utilizes a dry powder instead of liquid coatings. The powder is electrostatically applied to the surface of the product, creating a charged attraction for an even and uniform coating. Once the item is coated, it is then heated in a curing oven. The heat melts the powder particles, fusing them together and creating a smooth and durable finish.

Key Differences Between Baked Enamel And Powder Coat

1. Application Process:

The application process is the most noticeable difference between baked enamel and powder coat. Baked enamel is applied as a liquid by using various spray techniques, while powder coat is applied as a powder through electrostatic attraction.

2. Curing Method:

Another difference lies in the curing method. Baked enamel requires heating the coated item in a specialized oven, allowing the liquid coating to cure and harden. On the contrary, powder coat relies on the heat from the curing oven to melt and fuse the powder particles together, creating a durable finish.

3. Durability and Finish:

Both finishes offer excellent durability and weather resistance. However, baked enamel is known for its glossy, smooth finish, making it perfect for enhancing the visual appeal of a wide range of products. In contrast, powder coat finishes can provide a variety of texture options, including matte, gloss, and even metallic finishes.

4. Environmental Considerations:

From an environmental standpoint, powder coat is often considered a more eco-friendly option. The powder used in the process produces less waste and has lower levels of volatile organic compounds (VOCs) when compared to the liquid coatings used in baked enamel.

5. Cost and Availability:

| Baked Enamel | Powder Coat | |

|---|---|---|

| Cost | Budget-friendly | Slightly more expensive |

| Availability | Widely available | Increasing availability |

In terms of cost, baked enamel tends to be more budget-friendly, making it a preferred choice for projects with specific budget constraints. However, the availability of powder coat services is steadily increasing, providing more options for those who are looking for a wider range of finishes.

Pros And Cons Of Baked Enamel

When it comes to coating materials for various products, two commonly used options are baked enamel and powder coat. Both methods have their own advantages and limitations. In this section, we will focus on the pros and cons of baked enamel, which is a popular choice for many applications.

Benefits Of Baked Enamel

Baked enamel offers several benefits that make it an attractive choice for coating different surfaces. Some of the key advantages include:

- Durable and Long-lasting: Baked enamel coatings are known for their exceptional durability. They create a tough, resilient surface that can withstand everyday wear and tear, making them ideal for high-traffic areas or objects that are exposed to harsh conditions.

- Excellent Color Retention: One of the strengths of baked enamel is its ability to retain color over time. The intense heat during the baking process ensures that the pigment is fully bonded to the surface, preventing color fading due to sunlight or other environmental factors.

- Smooth and Even Finish: Baked enamel delivers a smooth and consistent finish, leaving no brush strokes or unevenness. This gives the coated surface a polished look, enhancing its overall appearance.

- Versatile Application: Baked enamel can be used on a wide range of materials, including metal, wood, and even glass. Its versatility makes it suitable for various industries, such as automotive, construction, and furniture.

- Resistance to Corrosion: Another advantage of baked enamel is its resistance to corrosion. The coating acts as a protective barrier, preventing moisture and other corrosive substances from reaching the underlying material, thus extending its lifespan.

Limitations Of Baked Enamel

While baked enamel has many benefits, it also has a few limitations that should be considered. Some of the key limitations include:

- Time-consuming Process: Baked enamel requires a precise and time-consuming application process, involving multiple stages such as surface preparation, application, and curing. This can add to the overall production time of a project.

- Higher Cost: Compared to some other coating options, baked enamel can be relatively more expensive due to the specialized equipment and meticulous process involved. However, the long-term durability and high-quality finish often outweigh the initial investment.

- Limited Color Options: While baked enamel does offer excellent color retention, the range of color options available can be more limited compared to powder coat. This can be a drawback for those seeking unique or customized color choices.

- Not Environmentally Friendly: Baked enamel coatings typically contain volatile organic compounds (VOCs), which can contribute to air pollution and have negative implications for the environment. Eco-conscious individuals may prefer alternative coating methods that have lower VOC content.

In summary, baked enamel coatings offer exceptional durability, color retention, and a smooth finish. They are suitable for various applications, but it’s important to consider the time-consuming process, higher cost, limited color options, and environmental impact. Understanding these pros and cons can help you make an informed decision when choosing between baked enamel and other coating options.

Pros And Cons Of Powder Coat

When it comes to coating metal surfaces, powder coat is a popular choice. It offers numerous benefits and a few drawbacks as well. In this section, we will explore the advantages and disadvantages of powder coat, allowing you to make an informed decision for your coating needs.

Advantages Of Powder Coat

Powder coat has several significant advantages that make it an appealing option for many applications:

- Durability: Powder coat is known for its exceptional durability. The coating creates a strong bond with the metal surface, providing excellent resistance against corrosion, scratches, and chipping. This makes it perfect for outdoor furniture, automotive parts, and other items that need to withstand harsh conditions.

- Wide Range of Colors and Finishes: Powder coat is available in a vast array of colors and finishes. Whether you prefer a glossy or matte look, metallic or textured finishes, powder coat can be tailored to suit your aesthetic preferences.

- Environmentally Friendly: Unlike other coating methods, powder coat does not emit volatile organic compounds (VOCs) into the air during the application process. This makes it a more eco-friendly option, as it has minimal impact on air quality.

- Cost-Effective: Powder coat is cost-effective for large-scale projects. The powder is applied efficiently, with little to no waste, saving you money on materials. Additionally, the coating’s durability reduces the need for frequent touch-ups or recoating, providing long-term cost savings.

Disadvantages Of Powder Coat

While powder coat offers numerous advantages, it is important to consider the following disadvantages:

- Thicker Coating: Compared to other coating methods, powder coat tends to create a thicker layer on the surface. This can affect the fit of tight tolerance parts or interfere with the functionality of moving components.

- Limited Repair Options: If a powder-coated surface gets damaged, repairing it can be challenging. Unlike liquid coatings that can be easily touched up or re-sprayed, powder coat often requires stripping off the entire coating and reapplying it. This can be time-consuming and costly.

- Temperature Sensitivity: The application process of powder coat involves baking the coated item in an oven at high temperatures. This means that certain materials or delicate objects might not be suitable for powder coat due to their temperature sensitivity, limiting the range of items that can be coated.

Application And Durability

When it comes to choosing coatings for various applications, both baked enamel and powder coat offer unique advantages. Understanding the application and durability of each option is crucial in making an informed decision. In this section, we will delve into the applications of baked enamel and powder coat, as well as compare their durability.

Baked Enamel In Various Applications

Baked enamel is a popular choice in industries where a durable and aesthetically pleasing finish is required. This coating process involves the application of a base coat followed by multiple coats of enamel. The coated object is then heated in an oven, allowing the enamel to cure and form a hard, smooth finish.

Baked enamel is commonly used in the automotive industry for painting vehicle bodies and parts. Its durability and resistance to chips, scratches, and UV rays make it ideal for withstanding the harsh conditions of the road. Additionally, baked enamel is often applied to metal furniture, appliances, and architectural components, providing a long-lasting and vibrant finish that enhances their appearance and protects against corrosion.

Powder Coat In Various Applications

Powder coat is a popular alternative to traditional liquid coatings. This method involves the electrostatic application of dry powder to a surface, which is then cured using heat, forming a durable and protective coating. Powder coat is available in a wide range of colors and finishes, providing versatility in terms of aesthetics.

One of the key advantages of powder coat is its excellent coverage and ability to coat complex shapes evenly. This makes it particularly suitable for coating metal furniture, outdoor equipment, and metal parts in the automotive and aerospace industries. The resistance of powder coat to fading, peeling, and cracking also makes it a reliable choice for outdoor applications exposed to harsh weather conditions.

Durability Comparison Between Baked Enamel And Powder Coat

Both baked enamel and powder coat offer exceptional durability, but they have slightly different characteristics in terms of performance. Baked enamel, with its multiple layers of paint and curing process, provides a robust and chip-resistant finish. It is highly resistant to wear and tear, making it suitable for high-traffic areas where objects are prone to abrasion or impacts.

Powder coat, on the other hand, offers comparable durability with excellent resistance to fading, chipping, and corrosion. The ability of powder coat to form a seamless and uniform coating makes it highly resistant to cracking and peeling, ensuring long-term protection and aesthetics.

A Summary of the Application and Durability of Baked Enamel vs Powder Coat:

| Baked Enamel | Powder Coat |

|---|---|

| Automotive industry for vehicle bodies and parts | Coating metal furniture and outdoor equipment |

| Metal furniture, appliances, and architectural components | Metal parts in the automotive and aerospace industries |

| Hard, smooth finish resistant to chips, scratches, and UV rays | Excellent coverage and resistance to fading, peeling, and cracking |

Ultimately, the choice between baked enamel and powder coat depends on the specific application and desired aesthetics. It is important to consider factors such as the object’s usage, exposure to environmental elements, and the desired level of durability. Consulting with a professional coating specialist can help ensure the right choice is made, resulting in a coating that performs well and enhances the longevity of the object.

Maintenance And Care

Proper maintenance and care of your baked enamel or powder coat finishes are essential for ensuring their longevity and keeping their appearance intact. By following the recommended maintenance requirements and implementing a few tips, you can significantly prolong the lifespan of your finishes and keep your items looking as good as new for years to come.

Maintenance Requirements For Baked Enamel

Baked enamel is a durable and resistant finish that is known for its excellent color retention and smooth finish. To keep your baked enamel finishes in top condition, here are some maintenance requirements to consider:

- Regular cleaning: Use a non-abrasive cleaner and a soft cloth to remove dirt, dust, and grime from the surface of the enamel. Avoid using harsh chemicals or abrasive materials that may damage the finish.

- Avoid scratching: Be cautious while handling and moving objects with baked enamel finishes, as they can be prone to scratching. Use protective pads or mats when placing items on surfaces to prevent any accidental scratches.

- Regular inspections: Periodically inspect your baked enamel finishes for any signs of damage or wear. Address any issues promptly to prevent further deterioration and maintain the integrity of the finish.

Maintenance Requirements For Powder Coat

Powder coat finishes offer excellent durability and resistance to chipping, fading, and corrosion. To ensure the long-lasting beauty of your powder-coated items, here are some maintenance requirements to keep in mind:

- Regular cleaning: Use a mild detergent and warm water to clean the powder coat finish. Gently scrub the surface with a soft brush or cloth, and rinse thoroughly to remove any residue. Avoid using abrasive cleaners or scrubbing tools that may damage the finish.

- Protective measures: Apply a wax or polish specially formulated for powder coat finishes to provide an additional layer of protection against UV rays and environmental factors. This will help to maintain the color and gloss of your powder-coated items.

- Examine for damages: Regularly inspect your powder coat finishes for any signs of damage, such as chips or scratches. If any issues are identified, touch up the affected areas quickly using a matching touch-up paint to prevent further damage.

Read More: Can You Polish Powder Coat?

Tips For Prolonging The Lifespan Of Baked Enamel And Powder Coat Finishes

By following these tips, you can extend the lifespan of your baked enamel and powder coat finishes:

- Avoid exposure to harsh chemicals or solvents that may cause damage to the finish.

- Protect your items from extreme temperature fluctuations, as they can affect the integrity of the finish.

- Regularly remove any debris or moisture that may accumulate on the surfaces of your items, as they can contribute to deterioration over time.

- Store your items in a dry and controlled environment when not in use, as excessive moisture can lead to rust or corrosion.

- If using your items outdoors, consider providing additional protection such as covers or shelters to shield them from harsh weather conditions.

By adhering to these maintenance requirements and implementing these tips, you can ensure that your baked enamel and powder coat finishes remain in optimal condition, providing lasting beauty and protection for your items.

Read Also: Does Powder Coating Fade in The Sun?

FAQs For Baked Enamel Vs Powder Coat

Is Powder Coating Better Than Enamel?

Powder coating is generally considered better than enamel due to its durability, resistance to chipping, and ability to create a more even finish. It also offers a wider range of colors and is eco-friendly.

What Is Baked Enamel Finish?

Baked enamel finish is a durable coating applied to surfaces like metal or porcelain. It is heated in an oven, creating a hard, smooth, and glossy finish. This finish protects against corrosion and provides a lasting, attractive appearance.

What Is A Baked Enamel Finish On Aluminum?

A baked enamel finish on aluminum is a protective coating created by baking a colored powder onto the metal surface. It provides durability, resistance to corrosion, fading, and scratching, making aluminum products suitable for various applications like automotive parts, appliances, and architectural components.

Is Powder Coat More Durable Than Paint?

Powder coat is more durable than paint due to its thick and tough finish, making it resistant to chipping, scratching, and fading. It provides excellent corrosion protection, making it ideal for outdoor applications. The curing process of powder coat also creates a strong bond, enhancing its durability.

Final Thoughts

Both baked enamel and powder coat are durable coating options for various surfaces. Baked enamel provides a glossy finish with excellent color retention, while powder coat offers a wide range of colors and finishes. Ultimately, the choice between the two depends on factors such as the intended use, desired aesthetics, and budget.

Proper application and maintenance will ensure the longevity and performance of either coating.