Yes, you can powder coat a car radiator. Powder coating is a durable and protective finish that can be applied to a variety of surfaces, including metal parts like a car radiator.

The process involves electrostatically spraying a dry powder onto the radiator and then baking it to create a hard and smooth finish that can withstand heat, corrosion, and weathering. Powder coating is often preferred over traditional paint because it provides a more even and consistent color, has a longer lifespan, and is resistant to chipping, peeling, and fading.

It can also enhance the overall appearance of the car radiator while protecting it from damage.

What Is Powder Coating And How Does It Work?

Powder coating is a popular method used to protect and enhance the appearance of various surfaces, including car radiators. The process involves applying a dry powder to a material and then curing it through heat, creating a smooth and durable finish. It is a highly efficient and eco-friendly alternative to traditional liquid coatings.

Definition of powder coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The powder is typically composed of a mixture of resin, pigment, and additives. It is electrostatically charged and adheres to the surface of the material. Once applied, the coated object is placed in an oven where the powder melts and fuses to the surface, forming a protective layer.

Overview of the powder coating process

The powder coating process consists of several steps:

1. Surface preparation: Before the powder is applied, the surface of the material needs to be cleaned and pre-treated. This involves removing any dirt, oil, or rust that may be present. Surface preparation is crucial to ensure proper adhesion and a smooth finish.

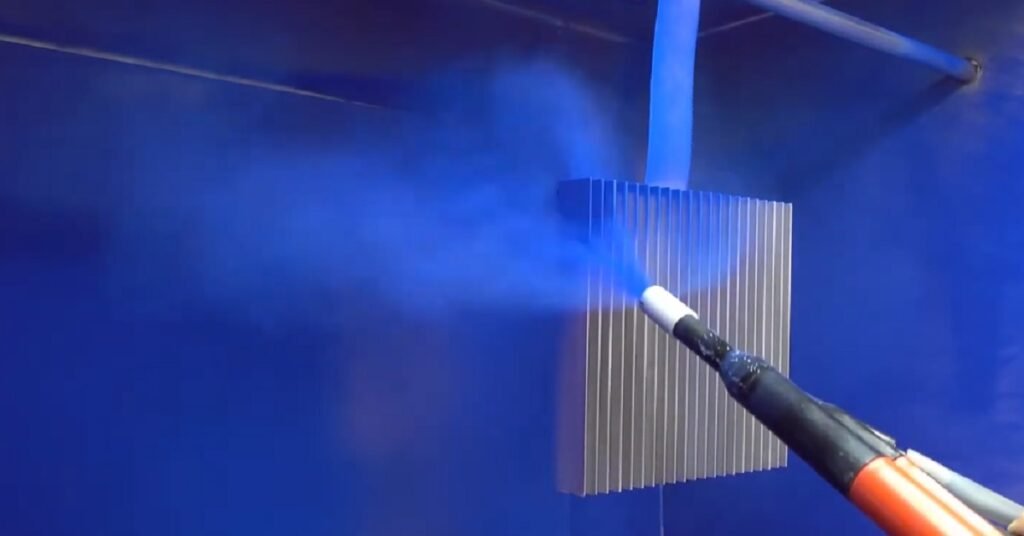

2. Application of the powder: The powder is applied using a spray gun or an electrostatic spray system. The charged particles are attracted to the grounded material, creating an even coating. The excess powder is reclaimed and recycled for future use, making powder coating a sustainable choice.

3. Curing: After the powder is applied, the coated object is heated in an oven. The heat causes the powder to melt and flow, forming a continuous film. The curing process typically takes between 10 to 30 minutes, depending on the type of powder and the thickness of the coating.

Explanation of how powder coating works on different materials

Powder coating works on a wide range of materials, including metals, plastics, and ceramics. The process is adaptable and can be customized to suit the specific requirements of different substrates.

Metals: Powder coating is commonly used on metals such as steel, aluminum, and brass. The coating provides excellent corrosion resistance, protection against UV rays, and a smooth, attractive finish. It can be applied to various metal objects, including car radiators, providing a long-lasting and durable coating.

Plastics: Powder coating can also be applied to certain types of plastics. However, not all plastics are suitable for powder coating, as they may melt or deform during the curing process. Specialized powders and curing techniques are used to ensure proper adhesion and a smooth finish on plastic substrates.

Ceramics: Powder coating can be used to enhance the appearance and durability of ceramic surfaces. The process involves carefully selecting a powder that can withstand the high temperatures required for curing. Once applied, the powder fuses with the ceramic, resulting in a vibrant and long-lasting finish.

Powder coating is a versatile and effective method for protecting and beautifying car radiators and other surfaces. Its ability to adhere to different materials and provide a durable finish makes it a popular choice among automotive enthusiasts. Whether you are looking to restore an old radiator or add a unique touch to your vehicle, powder coating is a reliable and aesthetically pleasing option.

Benefits Of Powder Coating A Car Radiator

Powder coating is a popular method for enhancing and protecting various parts of a car, and the radiator is no exception. By applying a layer of powdered paint to the radiator’s surface and then baking it, you can achieve a durable, corrosion-resistant, and visually appealing finish. Powder coating offers several benefits that make it an excellent choice for radiator customization. Let’s explore them in detail.

One of the significant advantages of powder coating a car radiator is its enhanced durability and corrosion resistance.

The powdered paint used in the process is composed of tiny particles made from pigments and resin. When it is baked, these particles melt and fuse together, forming a strong, continuous coating on the radiator’s surface. This coating provides exceptional resistance against chipping, cracking, and peeling, ensuring that your radiator stays protected even in harsh conditions.

Moreover, powder coating creates a seamless finish without any pores or voids, which prevents moisture and contaminants from seeping into the radiator. This protective layer acts as a barrier, greatly reducing the risk of corrosion and extending the lifespan of your car’s radiator.

Improved-heat-dissipation

In addition to its durability, powder coating enhances heat dissipation, which is crucial for the radiator’s functionality.

Due to its unique curing process that involves high temperatures, powder coating allows for better heat transfer from the radiator to the surrounding air. The smooth and even surface created by this method promotes efficient cooling performance, allowing the radiator to dissipate heat effectively. With improved heat dissipation, your car’s engine is less likely to overheat, leading to better overall performance and reduced risk of damage.

Extended-lifespan-of-the-radiator

Powder coating a car radiator significantly extends its lifespan compared to traditional painting methods.

The durable and corrosion-resistant coating provided by powder coating not only protects the radiator from environmental elements but also helps in maintaining its structural integrity. By minimizing the impact of rust and other damages, powder coating ensures that your radiator functions optimally for a more extended period.

Customization-options-for-aesthetics

Finally, powder coating offers a wide range of customization options for enhancing the aesthetics of your car radiator.

With an extensive palette of colors and finishes available, you can easily achieve the desired look that matches your personal style or complements your vehicle’s exterior. Whether you prefer a sleek matte black finish, a vibrant metallic color, or a textured look, powder coating allows you to create a unique radiator appearance that stands out.

In conclusion, powder coating a car radiator brings numerous benefits, including enhanced durability and corrosion resistance, improved heat dissipation, extended lifespan, and customization options for aesthetics. By choosing this method for radiator finishing, you can not only protect and prolong the life of your radiator but also achieve a visually appealing look that complements your vehicle.

Considerations Before Powder Coating A Car Radiator

Ensuring compatibility with the radiator material

When it comes to powder coating a car radiator, the first thing you need to consider is the compatibility with the radiator material. Radiators are typically made from different types of materials such as aluminum, steel, or copper. Each material has its own specific properties and characteristics, which need to be taken into account before proceeding with powder coating.

Proper preparation and cleaning of the radiator

Proper preparation and cleaning of the radiator surface is crucial before applying any powder coating. This ensures the adhesion of the powder and helps to create a smooth and even finish. To prepare the radiator surface, start by removing any dirt, grime, or old paint. This can be done using a degreaser or a non-abrasive cleaner. Make sure to rinse off any residue thoroughly and allow the radiator to dry completely before proceeding.

Addressing potential radiator damage or leaking issues

Before powder coating the radiator, it is important to inspect for any damage or leaks. Powder coating can help to protect the radiator surface, but it will not fix any existing issues. If you notice any signs of damage such as bent fins, cracks, or leaks, it is recommended to address these issues before applying the powder coating. Ignoring such issues can lead to further damage and reduced performance of the radiator.

Identifying any warranty concerns from manufacturers

Another consideration when powder coating a car radiator is to check for any warranty concerns from the manufacturers. Some radiator manufacturers may void the warranty if the radiator has been altered or modified in any way, including powder coating. It is important to review the warranty terms and conditions provided by the manufacturer before proceeding with the powder coating process.

Before powder coating a car radiator, it is essential to ensure compatibility with the radiator material, properly prepare and clean the radiator surface, address any potential damage or leaking issues, and consider any warranty concerns from the manufacturers. Following these considerations will help to ensure a successful powder coating process and maintain the performance and functionality of the car radiator.

Steps To Powder Coat A Car Radiator

When it comes to customizing your car, powder coating is a popular choice for achieving a durable and attractive finish. If you’re looking to revamp your car’s radiator, powder coating can give it a fresh new look while providing added protection against corrosion.

Disassembling The Radiator

Before you can begin the powder coating process, the radiator must be disassembled. This involves removing it from the car and taking apart any components that are attached to it, such as the fan or hoses. It’s important to ensure that all parts are properly identified and organized, as reassembling the radiator later will require attention to detail.

Preparing The Radiator Surface For Coating

Proper surface preparation is crucial to achieve a flawless powder coat finish on your car radiator. Start by thoroughly cleaning the radiator using a degreaser to remove any dirt, oil, or debris. Once clean, sandblasting the surface can help remove any remaining paint, rust, or corrosion. After sandblasting, a primer or metal prep solution can be applied to ensure optimal adhesion of the powder coating.

Table 1: Steps to Preparing the Radiator Surface

| Step | Description |

|---|---|

| 1 | Clean the radiator surface with a degreaser to remove any dirt or oil. |

| 2 | Sandblast the surface to remove old paint, rust, or corrosion. |

| 3 | Apply a primer or metal prep solution for optimal adhesion. |

Applying The Powder Coating

Once the surface is properly prepared, it’s time to apply the powder coating. Using an electrostatic spray gun, evenly distribute the powder coating material over the radiator surface. The electrostatic charge of the gun causes the powder to adhere to the metal, creating a uniform finish. Be sure to apply the coating in multiple thin layers to achieve the desired thickness and allow for consistent curing.

Curing The Powder Coating

To ensure the powder coating bonds effectively to the radiator, it needs to be cured. This is typically done in a specialized powder coating oven. The radiator should be placed inside the oven at the recommended temperature for a predetermined period of time. During the curing process, the powder coating undergoes a chemical reaction that hardens the coating, resulting in its final durable finish.

Reassembling The Radiator

Once the powder coating has been properly cured, it’s time to reassemble the radiator. Carefully follow the disassembly process in reverse, ensuring that all components are correctly aligned and securely fastened. Take extra caution with any gaskets, seals, or O-rings that were removed during the disassembly, as they play a crucial role in preventing leaks. After reassembling, it’s important to properly reinstall the radiator back into the car.

Now that you’re familiar with the steps involved in powder coating a car radiator, you can confidently give your radiator a fresh new look while enjoying the benefits of enhanced durability and corrosion resistance. Remember to follow safety precautions, such as wearing protective gear, and consult a professional if needed.

Expert Tips For Powder Coating A Car Radiator

Powder coating a car radiator is a great way to protect it from corrosion and enhance its overall appearance. The process involves applying a dry powder to the radiator’s surface, which is then cured to create a durable and long-lasting finish. However, to achieve the best results, it’s important to follow expert tips and guidelines.

In this section, we will explore some key considerations when powder coating a car radiator, including choosing the right coating type and color, proper handling techniques, temperature control during curing, and common mistakes to avoid.

Choosing The Right Powder Coating Type And Color

Choosing the right powder coating type and color is crucial for achieving the desired look and performance for your car radiator. When it comes to powder coating a car radiator, there are several types of coatings to choose from, including epoxy, polyester, and hybrid.

An epoxy powder coating is known for its excellent corrosion resistance and is often recommended for car radiators that are subjected to harsh conditions, such as extreme temperatures and moisture. It is available in a wide range of colors, allowing you to customize the look of your radiator.

Polyester powder coatings, on the other hand, offer good chemical resistance and are ideal for radiators that are exposed to chemicals and solvents. These coatings are available in a variety of finishes, such as matte, gloss, and textured, giving you the freedom to choose the perfect look for your radiator.

Hybrid powder coatings combine the benefits of both epoxy and polyester coatings, offering excellent corrosion resistance and color retention. This type of coating is a popular choice for car radiators due to its durability and versatility.

Once you have chosen the appropriate coating type, selecting the right color is the next step. A popular approach is to match the color of the radiator to the rest of the car’s exterior, creating a cohesive and stylish look. However, you can also opt for contrasting colors to make the radiator stand out as a focal point.

Proper Handling Techniques During The Coating Process

Proper handling techniques are crucial to ensure a smooth and successful powder coating process for your car radiator. Here are some key tips to keep in mind:

- Thoroughly clean and prepare the radiator surface before coating to remove any dirt, grease, or rust. This will help the powder coating adhere properly and prevent any imperfections.

- Use appropriate safety measures, such as wearing protective gloves and a mask, to avoid direct contact with the powder coating material and inhalation of harmful particles.

- Apply the powder coating evenly and in a controlled manner to ensure a uniform finish. Use a spray gun or an electrostatic powder coating system for precise application.

- Allow the coated radiator to cure in a well-ventilated area or a curing oven, following the manufacturer’s guidelines for temperature and duration. This will ensure the coating sets properly and maximizes its durability.

Managing Temperature Control During Curing

Temperature control is a critical factor during the curing process of a powder-coated car radiator. Improper temperature management can lead to subpar results or even damage the radiator. Here are some expert tips for managing temperature control:

- Ensure the curing oven or area is at the recommended temperature specified by the powder coating manufacturer. This will vary depending on the type of powder coating used.

- Monitor the temperature closely throughout the curing process to prevent overheating or underheating. Use a thermometer or temperature control device to maintain the optimal temperature range.

- Avoid rapid temperature changes during the curing process, as this can cause stress on the coating and affect its performance. Gradual temperature transitions are essential for achieving a strong and durable finish.

Avoiding Common Mistakes And Troubleshooting Tips

Even with careful planning and execution, mistakes can happen during the powder coating process. Here are some common mistakes to avoid and troubleshooting tips:

| Common Mistake | Troubleshooting Tip |

|---|---|

| Excessive powder coating thickness | Reduce the powder coat application to achieve a thinner and more even coating. Follow the manufacturer’s recommended thickness guidelines. |

| Inadequate surface preparation | Ensure the radiator surface is thoroughly cleaned, degreased, and free from rust or corrosion before applying the powder coating. Consider using sandblasting or chemical cleaning methods. |

| Improper curing conditions | Review the curing temperature and duration specified by the powder coating manufacturer and ensure proper ventilation during the process. Adjust the curing conditions if necessary. |

By following these expert tips and guidelines, you can achieve a professional and durable powder-coated finish for your car radiator, enhancing its performance and giving it a stylish look that will turn heads.

FAQs

How Much Does It Cost To Powder Coat A Radiator?

Powder coating a radiator typically costs around $100 to $200. Prices may vary depending on the size and complexity of the radiator. It’s a popular and durable coating option that enhances appearance and provides protection against corrosion and heat.

Are Powder Coated Radiators Any Good?

Yes, powder coated radiators are good. They have a durable finish that resists corrosion and gives a clean, modern look. The coating also helps to improve heat distribution and efficiency, making them an excellent choice for heating your space.

Can Powder Coating Withstand Heat?

Powder coating can withstand high temperatures without losing its performance. It is a durable and heat-resistant finish that can handle temperatures up to 400 degrees Fahrenheit or higher.

Final Thoughts

To sum up, powder coating a car radiator can be a viable option to enhance its durability and appearance. With its superior resistance to corrosion and ability to withstand high temperatures, powder coating can provide a long-lasting solution for radiator protection.

However, it’s essential to consider the specific requirements and compatibility of the radiator material before proceeding with the process. Ultimately, consulting with a professional can ensure the best outcome for your car radiator. So, don’t hesitate to explore this option and give your radiator a new lease on life.