Yes, brake calipers can be powder coated to enhance their appearance and performance. Powder coating provides a durable and attractive finish, offering protection against corrosion and high temperatures.

This process involves applying a dry powder to the calipers and then curing them in an oven to create a hard, smooth coating. Powder coating can be done in a variety of colors and finishes, allowing you to customize the look of your brake calipers to match your personal style or complement your vehicle’s aesthetics.

It is a popular choice among car enthusiasts and provides a long-lasting solution for improving the appearance and durability of brake calipers.

Why Powder Coating Is The Ideal Choice For Brake Calipers

Brake calipers play a crucial role in ensuring the safety and performance of your vehicle’s braking system. They are responsible for slowing down or stopping the rotation of the wheels when you apply the brakes. Given their critical role, it is essential to protect brake calipers against the harsh conditions they face on the road. That’s where powder coating comes in as the ideal choice for brake calipers.

Let’s explore the reasons why powder coating is the go-to option for enhancing the durability, corrosion resistance, and heat resistance of brake calipers.

Durable And Long-lasting Coating

Powder coating provides a durable and long-lasting protective layer for brake calipers. Unlike traditional liquid coatings, powder coating offers superior adhesion and strength. The powder coating process involves applying a fine powder to the caliper’s surface, which is then cured under heat, creating a tough and resilient coating. This durable coating ensures that your brake calipers can withstand the rigors of daily use and remain in excellent condition for an extended period.

Enhanced Corrosion Resistance

One of the main benefits of powder coating for brake calipers is its enhanced corrosion resistance. Brake calipers are exposed to various elements such as moisture, corrosive chemicals, and road salt. Over time, these factors can cause corrosion and deterioration of the caliper surface, compromising its performance and aesthetics. Powder coating creates a protective barrier that shields the caliper from corrosion, preventing rust formation and ensuring its longevity.

Superior Heat Resistance

Brake calipers generate a significant amount of heat during braking. This heat can cause conventional coatings to degrade, leading to discoloration, flaking, and reduced performance. Powder coating, on the other hand, exhibits superior heat resistance properties.

It can withstand high temperatures without losing its structural integrity or surface appearance. This heat resistance ensures that the powder-coated brake calipers remain visually appealing and fully functional even under extreme braking conditions.

How Powder Coating Transforms The Look Of Brake Calipers

Powder coating is a popular choice when it comes to adding an extra touch of style to your brake calipers. Not only does it offer a sleek and professional appearance, but it also provides a wide range of color options. With powder coating, you can customize your brake calipers to showcase your personal style and make your vehicle stand out on the road. Let’s explore how powder coating can completely transform the look of your brake calipers.

Wide Range Of Color Options

One of the significant advantages of powder coating brake calipers is the extensive array of colors available. Unlike traditional painting methods, powder coating offers a broad spectrum of hues and finishes to choose from. Whether you prefer classic black, vibrant red, or a unique metallic shade, powder coating allows you to select a color that perfectly complements your vehicle’s overall appearance. This customization option ensures that your brake calipers are not only functional but also serve as a stylish focal point.

Sleek And Professional Appearance

The powder coating process gives brake calipers a sleek and professional appearance that can elevate the aesthetics of any vehicle. The durable and smooth finish achieved through powder coating enhances the visual appeal of your brake calipers, making them look brand new and well-maintained.

Moreover, powder coating helps to protect the calipers from corrosion, road debris, and harsh weather conditions. This not only ensures long-lasting beauty but also contributes to the overall performance and lifespan of your brake calipers.

Customization For Personalized Style

Powder coating offers endless opportunities for customization, allowing you to add a personal touch to your vehicle’s brake calipers. Whether you aim for a subtle and refined look or a bold and eye-catching design, powder coating can bring your vision to life. From matte to gloss finishes, sparkles to textures, the options are endless.

With powder coating, you can embrace your individuality and make a statement on the road, showcasing your unique style and personality. The ability to personalize your brake calipers is not only a testament to your attention to detail but also a reflection of your automotive passion.

Powder coating brake calipers is a remarkable way to transform their look, offering a wide range of stunning color options, creating a sleek and professional appearance, and providing customization for a personalized style.

Whether you opt for a vibrant red or a classic black, powder coating is a durable and aesthetically pleasing choice that can enhance the overall look and performance of your vehicle’s brake calipers. Embrace this opportunity to make a statement on the road and showcase your unique style with powder-coated brake calipers.

Preparation And Cleaning Of Brake Calipers

The preparation and cleaning of brake calipers is a crucial step when it comes to powder coating them. Properly preparing and cleaning the calipers ensures that the powder coat adheres well, resulting in a long-lasting and durable finish. Now, we will discuss the necessary steps to take for effective preparation and cleaning of brake calipers.

Removal Of Brake Calipers

The first step in the process is to remove the brake calipers from the vehicle. This can usually be done by loosening the bolts that hold them in place, and carefully detaching them from the brake lines. It is important to refer to the vehicle’s manual or seek professional assistance to ensure the correct removal procedure specific to your vehicle.

Thorough Cleaning For Proper Adhesion

Once the brake calipers are removed, it is essential to thoroughly clean them to ensure proper adhesion of the powder coat. This step involves removing any dirt, grease, and debris that may be present on the surface of the calipers. Here are the key steps to follow:

- Start by using a wire brush or a sanding pad to remove any loose rust or paint from the calipers.

- Next, prepare a cleaning solution by mixing a degreaser or brake cleaner with warm water.

- Using a clean cloth or sponge, dip it into the cleaning solution and gently scrub the calipers to remove any stubborn dirt and grease. Be sure to cover all surfaces, including crevices and grooves.

- Rinse the calipers thoroughly with clean water to remove any remaining cleaning solution and residue.

- Allow the calipers to dry completely before proceeding with the powder coating process.

By following these steps, you will achieve a clean surface that is free from contaminants, allowing the powder coat to adhere properly and provide a flawless finish. Remember, proper cleaning is vital for ensuring the longevity of your powder-coated brake calipers.

Applying The Powder Coating

Electrostatic Application

When it comes to applying powder coating to brake calipers, the electrostatic application method is commonly used. This method ensures that an even and thorough coating is achieved, resulting in a visually appealing finish.

The electrostatic application process involves the use of a spray gun that applies an electrostatic charge to the powder particles as they are sprayed onto the calipers. The calipers themselves are grounded and attract the charged particles, creating a bond that helps the powder adhere to the surface.

What makes electrostatic application ideal for powder coating is its ability to ensure full coverage, even on complex shapes like brake calipers. The charged powder particles are attracted to every nook and cranny of the calipers, creating a consistent and uniform coating. This means that every part of the caliper, from the faces to the edges and crevices, receives the protective powder coating.

Curing Process For A Hard And Protective Finish

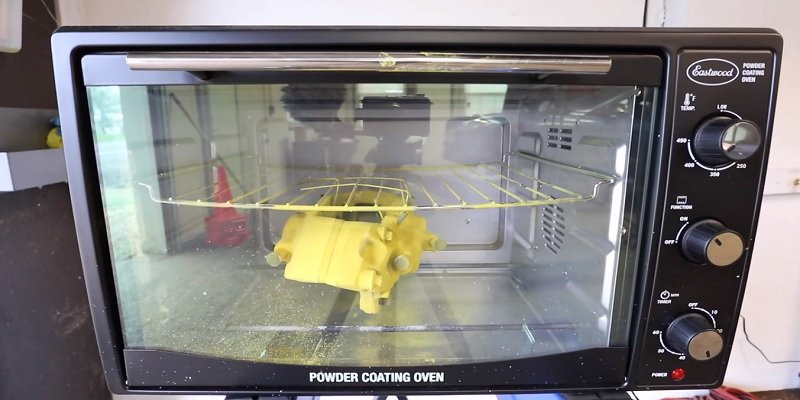

Once the powder coating has been applied to the brake calipers, the curing process begins to create a hard and protective finish. Curing involves subjecting the coated calipers to high temperatures for a specific period of time. This process activates the crosslinking agents in the powder, causing it to melt and flow, creating a durable and resilient surface.

The curing process can take place in a specialized oven designed for powder coating applications. The calipers are placed in the oven and heated to the recommended temperature for the specified duration. During this time, the powder particles melt and fuse together, forming a continuous coating that adheres strongly to the caliper surface.

Proper curing is essential to ensure the longevity and durability of the powder-coated brake calipers. The correct temperature and time specifications must be followed to achieve optimal results. This hard and protective finish not only enhances the appearance of the calipers but also provides resistance to corrosion, chipping, and fading.

Any Risks Or Considerations With Powder Coating Brake Calipers?

Powder coating brake calipers is a popular choice for automotive enthusiasts who want to give their vehicle a fresh, customized look. However, before diving into this color-enhancing process, it’s important to consider any potential risks or concerns that may arise. Let’s take a closer look at two key aspects to keep in mind when considering powder coating brake calipers: the impact on brake performance and safety, and the potential for damage during removal and reinstallation.

Impact On Brake Performance And Safety

When it comes to powder coating brake calipers, one of the primary concerns is how it might impact the overall performance and safety of the braking system. Brake calipers play a crucial role in stopping your vehicle, so it’s essential to ensure that their functionality remains intact after powder coating.

During the powder coating process, heat is applied to cure the powder, creating a durable, protective coating on the calipers. While this process can enhance the calipers’ resistance to corrosion and provide an attractive finish, it’s important to note that excessive heat exposure can potentially affect the caliper’s metallurgical properties.

Additionally, the thickness of the powder coating can impact the caliper’s fit and clearances. If the coating is too thick, it may interfere with the brake pads or prevent proper movement of the caliper, potentially compromising brake performance and safety.

Potential For Damage During Removal And Reinstallation

Before powder coating brake calipers, they must be removed from the vehicle. This process involves disconnecting brake lines, brake pads, and any other components attached to the calipers. While removing the calipers is relatively straightforward, it’s essential to exercise caution to avoid any damage that may affect the braking system.

During reinstallation, it’s crucial to ensure that all components are properly aligned and tightened to avoid any potential issues. If the calipers are not reinstalled correctly, it can lead to brake fluid leaks, uneven brake pad wear, or even a loss of braking power, jeopardizing both the safety of the vehicle and its occupants.

It’s worth noting that some car manufacturers don’t recommend powder coating brake calipers due to the risks involved. It’s always best to consult with a professional automotive technician who has experience with powder coating and brake systems to ensure the process is carried out correctly and doesn’t compromise the safety or performance of your vehicle.

Factors To Consider In Selecting A Powder Coating

When it comes to powder coating your brake calipers, there are several factors to consider in order to achieve the best results. Selecting the right powder coating can make a significant difference in terms of durability, color options, and compatibility with your brake caliper material. Let’s delve into these factors in more detail.

Durability And Resistance To Wear And Tear

When powder coating your brake calipers, durability and resistance to wear and tear are crucial aspects to consider. Brake calipers are constantly exposed to high temperatures, friction, and harsh environmental conditions. Therefore, it is essential to choose a powder coating that can withstand these challenges and provide long-lasting protection.

Look for a powder coating that offers excellent adhesion, hardness, and resistance to chipping, corrosion, and fading. Additionally, consider the specific demands of your vehicle’s brake system, such as whether it is used for daily driving or high-performance applications. Opting for a powder coating specifically designed for brake calipers will ensure optimal durability and protection for years to come.

Color Options And Finish Varieties

One of the advantages of powder coating brake calipers is the wide range of color options and finish varieties available. Whether you want to match your vehicle’s paint color, create a contrasting effect, or even showcase a unique metallic or chrome finish, there is a powder coating to suit your preferences.

Popular color options include classic black, red, blue, yellow, and various shades of metallic finishes. Different powder coat manufacturers may offer a different selection of colors, so it’s worth exploring various options to find the perfect match for your brake calipers.

Compatibility With Brake Caliper Material

It’s important to ensure that the powder coating you choose is compatible with your brake caliper material. Brake calipers can be made from various materials such as cast iron, aluminum, stainless steel, or even composite materials. Each material has different properties and may require specific types of powder coatings.

Check with the powder coating manufacturer or a professional powder coater to determine the compatibility of the coating with your specific brake caliper material. Ensuring a proper match will guarantee optimal adhesion, durability, and overall performance of the coated brake calipers.

When powder coating your brake calipers, keep in mind the factors of durability and resistance to wear and tear, color options and finish varieties, as well as compatibility with your brake caliper material. Selecting the right powder coating will not only enhance the visual appeal of your brake calipers but also provide long-lasting protection and reliable performance.

Top Powder Coating Brands For Brake Calipers

When it comes to powder coating brake calipers, using high-quality products from reputable brands is essential. These top powder coating brands offer a range of products and features that can help you achieve an amazing finish for your brake calipers. In this article, we will take a closer look at three leading companies in the market.

Powder Coating In San Antonio: Best Powder Coating Service For Brake Calipers

We known for exceptional powder coating products specifically designed for brake calipers. With a wide range of vibrant colors and finishes to choose from, we offer endless possibilities for customizing your calipers. Some notable features are include:

- High heat resistance to ensure durability under extreme braking conditions

- Excellent adhesion to the caliper surface for long-lasting results

- Quick curing time for faster completion of the powder coating process

- Compatibility with various caliper materials, including cast iron and aluminum

Whether you want a glossy finish or a matte look, We have the right product to suit your preferences. Our powder coatings are known for our outstanding quality and ease of application, making them a popular choice among car enthusiasts.

Unit F14 Powder Coating: 1705 Capital Ave Plano, TX 75074

Unit F14 has established itself as a reliable provider of powder coating solutions for brake calipers. They offer a range of products that boast excellent performance and stunning aesthetics. Here are some key features of Unit F14 offerings:

- Superior resistance to fading, chipping, and scratching, ensuring the longevity of the coating

- Wide selection of colors and finishes, including metallic and textured options

- Quick and easy application process, even for beginners

- Chemical and corrosion resistance for enhanced durability

Whether you drive a sports car or a SUV, Company B’s powder coating products have been designed to withstand the demands of the road while adding a touch of style to your brake calipers. Their reputation for quality and innovation has made them a trusted choice among car enthusiasts worldwide.

Avior Performance: Brake Caliper Powdercoating Services in Houston

Avior Performance has gained recognition for its high-performance powder coating solutions for brake calipers. With an emphasis on durability and aesthetics, they offer products that are both functional and visually appealing. Here are some noteworthy features of Avior Performance’s offerings:

- Extreme heat resistance, ensuring the coating remains intact even under intense braking

- Wide range of vibrant colors, including custom color matching options

- Strong adhesion for a long-lasting finish

- Resistance to brake fluid and other chemicals

Avior Performance understands the importance of striking a balance between performance and appearance. Their powder coatings provide an excellent combination of functionality and visual impact, making them a popular choice among car enthusiasts who want the best of both worlds.

Pros And Cons Of Diy Powder Coating

Thinking of giving your brake calipers a fresh and vibrant look? Powder coating is a popular option that offers durability and a wide range of color choices. While hiring a professional to powder coat your brake calipers is one route to take, some automotive enthusiasts prefer to take on this project themselves. In this section, we’ll explore the pros and cons of DIY powder coating, providing you with an informed perspective before you embark on such a task.

Cost Savings

One of the primary advantages of DIY powder coating is the cost savings it offers. By opting to do the powder coating yourself, you can avoid the expense of professional services, potentially saving a significant amount of money. Powder coating kits and supplies are readily available online and can be purchased at a fraction of the cost of professional powder coating services.

However, it’s important to note that while you may save money on labor costs, the initial investment for the necessary equipment and supplies can be significant. Powder coating requires specialized tools, such as a powder coating gun, an oven or a curing lamp, and a suitable workspace. These expenses must be taken into account when considering the overall cost savings.

Requirement Of Specialized Equipment And Knowledge

Undertaking a DIY powder coating project also means that you need to have access to specialized equipment and knowledge. Powder coating involves several steps, including cleaning, prepping, applying the powder, and curing. Each step requires precision and attention to detail.

To achieve professional-looking results, you need to have a good understanding of the equipment and materials involved, as well as the proper techniques for each stage of the process. Without the necessary knowledge, your DIY powder coating project may not yield the desired results, and you risk wasting time and materials.

Moreover, a suitable and well-ventilated workspace is crucial for the powder coating process. The area needs to be clean, free from moisture, and equipped with proper ventilation to ensure the safety and effectiveness of the coating process. Failure to create an appropriate workspace can lead to subpar results or even safety hazards.

In summary, the decision to DIY powder coat your brake calipers comes with both advantages and considerations. Cost savings can be achieved by avoiding professional services, but the initial investment in equipment must be considered. Additionally, specialized equipment and knowledge are prerequisites for successful powder coating, making it essential to have the necessary skills and a suitable workspace. By weighing these pros and cons, you can make an informed decision about whether DIY powder coating is the right choice for your brake calipers.

Benefits Of Professional Powder Coating Services

When it comes to enhancing the appearance and performance of your brake calipers, professional powder coating services offer remarkable advantages. Whether you’re aiming to give your vehicle a fresh, personalized look or seeking to improve the durability and resistance of your brake components, powder coating is an ideal solution. By entrusting your brake calipers to experienced professionals, you can enjoy the following benefits:

Quality Assurance And Expertise

By opting for professional powder coating services, you ensure that your brake calipers are in the hands of experts. These professionals possess the necessary knowledge and skills to deliver a high-quality powder coating job. They are well-versed in different techniques, application methods, and color choices, allowing them to execute flawless coatings with precision and expertise.

With years of experience in the industry, professional powder coating service providers know exactly how to prepare, clean, and treat brake calipers before applying the powder coat. This meticulous attention to detail ensures an even and durable finish while preventing issues such as peeling or chipping.

Time And Effort Saved

Your time is valuable, and opting for professional powder coating services can save you significant amounts of it. The process of powder coating brake calipers involves multiple steps, from surface preparation to curing. Professionals possess the necessary equipment, facilities, and expertise needed to streamline this process, reducing the time and effort required on your part.

When you choose professional powder coating services, you eliminate the need for time-consuming tasks such as sanding, priming, and applying multiple coats of paint. The professionals will handle all the necessary steps efficiently, allowing you to focus on other aspects of your vehicle customization or maintenance.

Warranty And Guarantee Coverage

One of the additional advantages of professional powder coating services is the warranty and guarantee coverage they provide for their work. Reputable service providers stand by the quality of their craftsmanship and offer warranties on their powder coating jobs. This means that if any issues arise with the coating, such as peeling or fading, the service provider will rectify the problem at no additional cost to you.

With warranty and guarantee coverage, you can rest easy knowing that your brake calipers are protected and that the professionals are committed to your satisfaction. This added peace of mind further confirms the reliability and trustworthiness of professional powder coating services.

FAQs For Can You Powder Coat Brake Calipers?

Should You Powder Coat Brake Calipers?

Yes, powder coating brake calipers is recommended. It provides a durable and long-lasting finish that protects against corrosion, heat, and brake dust. Moreover, it enhances the appearance of your vehicle and allows for customization with various color options. Proper preparation and application ensure optimal results.

How Much Does It Cost To Powder Coat Brake Calipers?

The cost of powder coating brake calipers varies, but on average, it can range from $200 to $500.

Do You Have To Disassemble Brake Calipers To Powder Coat?

No, you don’t need to disassemble brake calipers for powder coating.

How Many Pounds Of Powder Coat For Brake Calipers?

For brake calipers, the amount of powder coat needed depends on their size and design. On average, it may require around 1-2 pounds of powder coat. However, it’s best to consult with a professional to determine the exact amount required based on your specific calipers.

Final Thoughts

To sum up, powder coating brake calipers is a popular and effective way to enhance the appearance of your vehicle while providing long-lasting protection. It offers advantages such as durability, resistance to fading, and a wide range of color options.

Ultimately, powder coating brake calipers can help showcase your personal style and add a touch of uniqueness to your ride. Upgrade your braking system today!