In this guide, you’ll learn Can you powder coat over an existing powder coat? or Not and:

- Reasons to Powder Coat Over an Existing Powder Coat

- Benefits of Powder Coating Over Powder Coating

- When Recoating Is a Good Idea

- How to Apply Second Coat of Powder Coating

- FAQs

And much more! Let’s dive in.

Understanding Powder Coating

Before we dive into the possibilities of recoating, let’s first establish a solid foundation by understanding the basics of powder coating.

Powder coating is a dry finishing process that involves applying a fine powder to a surface. The powder is electrostatically charged and then heated to create a hard, smooth, and durable finish. It’s commonly used on metal surfaces but can also be applied to various other materials, making it a versatile choice for many industries.

Can You Powder Coat Over Powder Coat?

Now, the burning question: Can you powder coat over an existing powder coat? The answer is a resounding yes, but it’s not always a straightforward process. Let’s break it down.

Reasons to Powder Coat Over an Existing Powder Coat

There are several reasons why you might consider recoating an existing powder coat:

- Color Change: If you want to update the color of the coated item, recoating is an excellent option.

- Damage Repair: In the event of damage to the existing coat, recoating can restore the surface’s integrity.

- Improved Finish: Maybe you’re aiming for a different finish, such as a glossy or matte look.

- Enhanced Durability: Adding another coat can increase the overall durability and longevity of the finish.

Exploring the Benefits of Powder Coating Over Powder Coating

Powder coating is a popular finishing option among commercial and industrial product manufacturers because of its durability, affordability, and easy application. It is the most cost-effective and reliable method of protecting and providing aesthetics to metal surfaces. However, it is not the only option when it comes to finishing.

Powder coating over powder coating (PCOPC) has become a popular alternative and can offer even more advantages for the end user. PCOPC is a process in which two different powder coatings are applied one after the other. The first coating provides the desired aesthetics and protects the metal surface from damage and corrosion.

The second coat provides additional protection from the elements and other factors that can degrade the finish. The most obvious benefit of PCOPC over traditional powder coating is its increased protection.

Double powder coating creates a sandwich-like barrier system that seals out moisture and sunlight, and prevents scratching and other physical damage. This ensures that the powder coating finish of any product remains intact and attractive for a much longer period of time. Another advantage of PCOPC is its superior appearance.

The two-coat system increases the thickness of the finish, which adds depth to the color and gives the surface a more uniform look. Additionally, it makes the finish more resistant to fading, ensuring that the product looks like new for many years.

Finally, PCOPC often costs less than traditional powder coating. Since two layers are being applied, the initial setup costs may be higher than a single coat but the overall cost for the entire job may be lower due to the increased durability.

Ultimately, PCOPC is an excellent choice for those who want to ensure maximum protection and excellent aesthetics for their products. It provides enhanced protection, superior appearance, and often costs less than traditional powder coating. As such, it is an ideal finishing option for those looking to finish a metal surface.

When Recoating Is a Good Idea

Now that we’ve covered the considerations and potential challenges, let’s explore when recoating with powder can be a smart choice.

Cost-Effective Refresh

One of the primary reasons for recoating is cost-effectiveness. Rather than stripping the old powder coat, which can be time-consuming and costly, applying a new coat over it is a more economical solution. This is particularly attractive when you have a large item or multiple pieces to recoat.

Minor Damage Repair

If the existing powder coat has minor damage or imperfections, recoating can be an effective way to repair and refresh the finish. It can cover up small scratches, scuffs, or areas where the powder has chipped, giving the item a rejuvenated look.

Color Change or Customization

Sometimes, you may want to change the color of a powder-coated item or add a unique custom design. Recoating provides the flexibility to transform the appearance of the item without the need for extensive stripping and repainting. This can be particularly appealing in situations where you’re looking to update the look of your vehicle, bicycle, or home appliances.

Environmental Benefits

From an environmental standpoint, recoating with powder is an eco-friendly option. Unlike traditional liquid paints, powder coatings contain no solvents, resulting in fewer volatile organic compounds (VOCs) released into the atmosphere. By avoiding the need to strip the old coating, you also reduce the generation of hazardous waste.

Real-Life Examples

To put the concept of recoating with powder into perspective, let’s explore a couple of real-life examples where this process can be highly beneficial.

Example 1: Automotive Wheel Refinishing

Imagine you have a set of aluminum alloy wheels on your car. Over time, the original powder coating on the wheels has started to show signs of wear, with chips and scratches affecting their appearance. However, the wheels are still structurally sound, and you don’t want to invest in new ones.

In this scenario, recoating the wheels with a fresh layer of powder coating can be a fantastic solution. After thorough surface preparation, including cleaning and perhaps sandblasting to enhance adhesion, a skilled technician can apply the new coating. This not only repairs the damage but also gives you the opportunity to change the wheel color or design to match your car’s updated style.

Example 2: Industrial Equipment Maintenance

Powder coating is widely used in industrial applications for its durability and resistance to corrosion. Over time, industrial equipment may experience wear and tear, including damage to the powder-coated finish. Instead of replacing costly equipment or dealing with downtime, recoating is a practical choice.

Suppose you have a piece of heavy machinery with a worn and faded powder coating. Recoating it can extend the equipment’s lifespan and improve its aesthetic appeal. It’s a cost-effective way to maintain your assets without the expense of buying new equipment.

Understand the Process of Powder Coating Over Powder Coating

Powder coating is a popular coating process that involves the application of an electrically charged powder of varying material composition over a substrate. This coating is then heated until it melts and bonds to the substrate, creating a protective layer Powder coating is a popular choice for many industries due to its superior durability, aesthetic appeal, and overall cost-effectiveness.

Powder coating over powder coating is a process by which a second layer of powder coating is applied to a previously powder coated substrate. This process provides several advantages, including an even more durable run with enhanced UV and corrosion protection, while also allowing for different colors and textures to be applied simultaneously in order to achieve an aesthetically pleasing finish.

The process of powder coating over powder coating begins with the preparation of the previously coated substrate. This requires the removal of any irregularities or imperfections, as well as the sanding or buffing of the substrate in order to ensure a good bond between the two layers of powder coating.

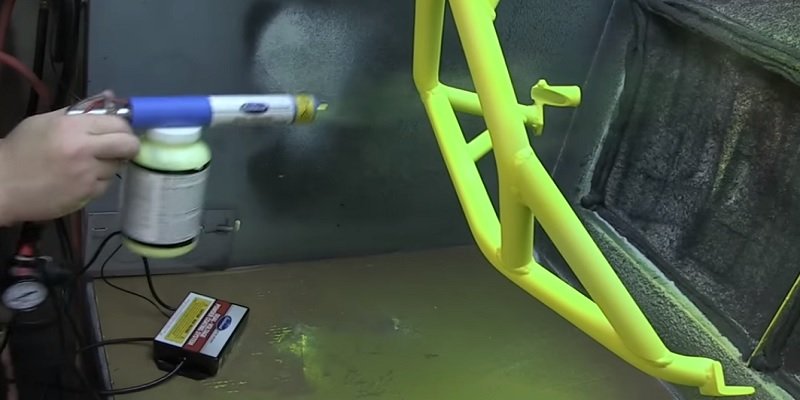

Once the substrate is prepped, the substrate is sprayed with a primer or ground coat, applied with an electrostatic gun. This ground coat is generally the same material as the top coat to ensure consistent coverage and adhesion. Once the primer is applied, the top coat is then sprayed over the substrate.

The top coat is generally a different color than the ground coat, and a smooth, even finish is achieved by using a special powder application technique.

Finally, the substrate is placed into an oven and heated in order to melt and cure the powder and ensure a durable finish. Powder coating over powder coating is a process that is used in many industries due to its superior durability, cost-effectiveness, and high-quality finish. With proper preparation, this process can yield an aesthetically pleasing and durable product.

How to Apply Second Coat of Powder Coating? Step-by-Step Guide

To apply a second coat of powder coating, start by cleaning the surface and ensuring it is completely dry. Next, apply a thin and even layer of the powder using a spray gun, making sure to cover the entire surface.

Let’s dive in! Step by step guide:

1. Surface Preparation

Before applying the second coat, ensure that the substrate is clean and free of any contaminants, such as dirt, oil, or rust. This is crucial for good adhesion and a flawless finish.

2. Selecting the Right Powder

Choosing the correct powder is vital. It should be compatible with the first coat and provide the desired finish. Mixing different types of powder may lead to adhesion issues and an uneven appearance.

3. Electrostatic Application

Utilize an electrostatic spray gun to apply the second coat. This tool imparts an electrical charge to the powder particles, causing them to adhere evenly to the grounded substrate. This results in a smooth, uniform coating.

4. Maintain Proper Distance

Maintain the correct distance between the spray gun and the surface. Typically, this is around 6 to 8 inches. Be sure to follow the manufacturer’s recommendations for your specific powder and equipment.

5. Apply a Light Second Coat

The second coat should be lighter than the first. A heavy application can lead to excessive thickness, which may cause issues like orange peel or sagging. A lighter coat ensures a more even and attractive finish.

6. Cure the Second Coat

After applying the second coat, it’s time to cure it. Follow the curing instructions provided by the powder manufacturer. This usually involves baking the coated item in an oven at the specified temperature for the recommended duration.

7. Cool Down and Inspect

Once the curing process is complete, allow the coated item to cool down. After it reaches room temperature, inspect the finish carefully. Look for any imperfections, and if necessary, you can perform touch-ups before final curing.

8. Final Cure

If touch-ups are required, re-cure the item according to the manufacturer’s instructions. Ensure that the entire surface undergoes the final curing process to maintain consistency.

Common Challenges and Solutions

While applying a second coat of powder coating, you may encounter some common challenges. Let’s explore these issues and their solutions:

1. Orange Peel

Orange peel refers to a textured, dimpled appearance in the coating, resembling the skin of an orange. To prevent this, ensure the powder is properly mixed, and the application is consistent. Adjusting the spray gun settings can also help achieve a smoother finish.

2. Sagging

Sagging occurs when the powder coating sags or drips due to excessive thickness. To avoid this issue, apply a lighter second coat and adhere to the recommended cure time and temperature.

3. Color Variation

Inconsistent color can be a concern when applying a second coat. To overcome this, ensure the second coat is applied evenly and consistently. Proper curing is also crucial to achieve the desired color.

How to Achieve a Lasting Finish With Powder Coating Over Powder Coating

Surface Preparation

Proper surface preparation is crucial when considering recoating with powder. The surface should be thoroughly cleaned to remove any contaminants, such as grease, oil, dirt, or loose powder particles. This step is crucial for ensuring good adhesion between the new and old coats.

Abrasive methods, like sandblasting or abrasive blasting, can also be used to create a profile on the existing powder coat, enhancing adhesion for the new coat. This is particularly important if the old coat is extremely smooth or glossy, as adhesion can be a challenge in such cases.

Thickness and Compatibility

Another vital factor to consider is the thickness of the existing powder coat. If the previous coating is too thick, it might not be ideal for adding another layer. Thick coats can lead to issues with curing and adhesion.

Compatibility between the old and new powder coats is also crucial. It’s advisable to use the same type or brand of powder coating to ensure compatibility. If you’re uncertain about compatibility, conducting a test on a small, inconspicuous area can help you avoid potential issues.

Curing Process

Powder coating involves a curing process that requires the coated item to be baked at a specific temperature. When recoating over an existing powder coat, it’s essential to ensure that the curing temperature and time are adequate for both the new and old coats. This will help avoid problems like under-curing, which can result in a subpar finish.

Appearance and Quality

While it is technically possible to apply a new powder coat over an old one, you should be aware that doing so may not always yield the desired results. The final appearance and quality of the finish can be affected by various factors, including the color of the new coat, the condition of the old coat, and the skill of the person applying the coating.

For example, if you’re recoating a dark-colored powder coat with a lighter shade, achieving full coverage may be challenging. The old color might still be visible through the new coat, requiring multiple layers and additional time and effort.

Additionally, any defects or imperfections in the old powder coat, such as bubbles or uneven areas, will likely remain visible after recoating. It’s important to manage your expectations and assess whether the final appearance meets your standards.

Tips for Successful Recoating

If you’re considering recoating with powder, it’s essential to follow some key tips to ensure a successful outcome.

Tip 1: Work with a Skilled Professional

Recoating with powder requires skill and expertise. To achieve the best results, it’s recommended to work with a professional who has experience in powder coating. They will have the knowledge and equipment needed to properly prepare the surface and apply the new coat.

Tip 2: Surface Preparation

Surface preparation cannot be stressed enough. Cleaning the item thoroughly and creating the right surface profile, if necessary, are essential steps in the recoating process. Properly prepared surfaces lead to better adhesion and a more durable finish.

Tip 3: Compatibility Testing

If you’re uncertain about the compatibility of the old and new powder coats, conduct a small-scale compatibility test on a hidden or inconspicuous area. This will help you determine if any issues, such as adhesion problems or color bleed-through, are likely to arise.

Tip 4: Layer Thickness

Be mindful of the thickness of the powder coating layers. Excessive thickness can lead to curing problems and affect the final appearance. Ensure that the combined thickness of the old and new coats falls within acceptable ranges.

Tip 5: Curing Parameters

Pay close attention to the curing process. The temperature and duration of curing should be appropriate for both the old and new coats. Deviations from recommended curing parameters can lead to problems like under-curing or over-curing, affecting the finish’s quality.

Tip 6: Manage Expectations

Finally, manage your expectations regarding the final appearance. Recoating can work wonders for refreshing an item’s look, but it may not make it look brand new, especially if the old coat had significant defects. Keep in mind that the quality of the finish depends on various factors and may not always be perfect.

FAQs:

Can I recoat a powder-coated surface without stripping the old coating?

Yes, you can recoat without stripping, but only if the existing coating is in good condition. If it’s damaged or peeling, it’s best to remove it before applying a new coat.

What’s the difference between epoxy and polyester powders for recoating?

Epoxy powders are known for their excellent adhesion properties, making them a good choice for recoating. Polyester powders offer better UV resistance, so the choice depends on your specific needs.

How many times can you recoat a powder coat?

While it’s possible to recoat multiple times, it’s essential to monitor the thickness to avoid any issues with adhesion and durability.

Can you powder coat over rust?

It’s not recommended to powder coat over rust, as it can affect the finish’s quality. Proper rust removal is crucial before recoating.

What is the ideal thickness for a powder coat?

The ideal thickness typically ranges from 2 to 4 mils (50 to 100 microns), but it can vary based on the specific application and requirements.

Can you recoat with a different type of powder?

Yes, it’s possible to recoat with a different type of powder, but compatibility and adhesion should be considered.

Is professional help necessary for recoating?

While recoating can be a DIY project for experienced individuals, professional assistance is recommended for the best results.

How long does the curing process take?

The curing process usually takes around 20-30 minutes at a temperature of 375-400°F (190-204°C).

Conclusion

In conclusion, the answer to the question “Can you powder coat over powder coat?” is a definite yes. Recoating offers versatility and the opportunity to enhance the appearance and durability of the finish. However, it’s essential to follow the proper procedures and, in some cases, seek professional assistance to achieve the best results.

Whether you’re looking to update the color, repair damage, or simply improve the finish of your powder-coated items, recoating can be a viable solution. Remember to pay attention to surface preparation and adhere to the necessary steps for a successful outcome.

If you’re considering recoating, always keep in mind the compatibility of the new powder with the existing coat. Additionally, for more complex projects or if you’re uncertain about the process, it’s wise to consult with a professional to ensure a flawless finish.

So, if you’re wondering about recoating powder coats, you now have the information you need to make an informed decision. Give your items a fresh, durable, and attractive finish with the power of powder coating.