Powder coating can withstand temperatures up to 1000 degrees Fahrenheit, making it a durable and heat-resistant coating option for various applications. Powder coating offers excellent protection against high temperatures, ensuring long-lasting performance and appearance.

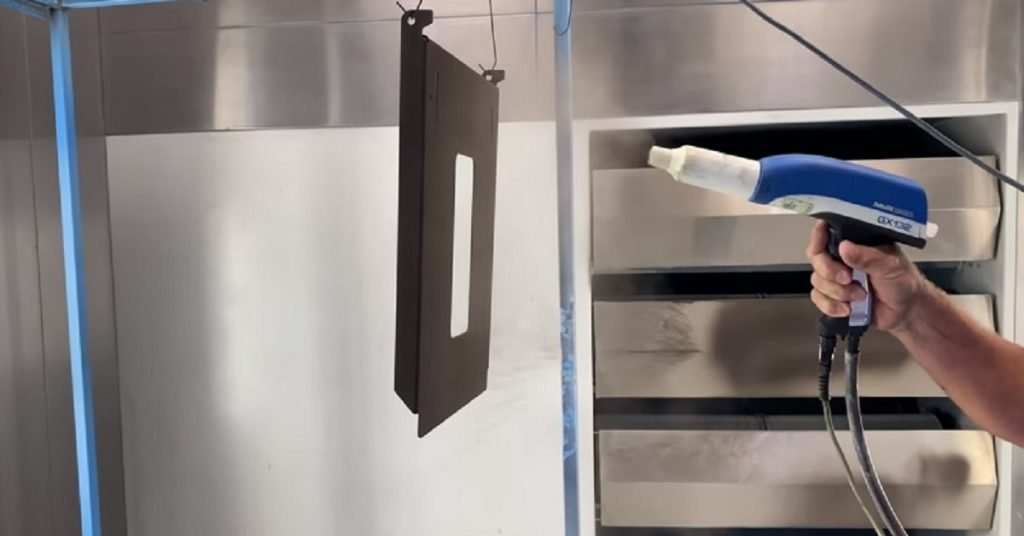

Powder coating is a popular choice for protecting and enhancing the surface of different objects, ranging from household appliances to automotive parts. This coating process involves applying a dry powder to a substrate and then curing it through heat, resulting in a tough and attractive finish.

One of the key factors that determine the suitability of powder coating for different environments is its ability to withstand extreme temperatures. Understanding the temperature limits of powder coating is crucial for ensuring its effectiveness and longevity.

We will explore the temperature resistance of powder coating and its implications for different applications. So, let’s dive in and discover what temperatures powder coating can withstand.

What Temperature Can Powder Coating Withstand?

Powder coating is known for its exceptional heat resistance. The specific temperature range that powder coating can withstand depends on the type of powder used and its formulation. As a general guideline, powder coating can typically withstand temperatures between 120°C (250°F) and 205°C (400°F).

It is vital to select the appropriate type of powder coating for applications that involve exposure to high temperatures. For instance, there are specialized powders designed for applications in industries like automotive, aerospace, or even certain household appliances that require enhanced heat resistance.

By choosing the right powder coating, you can ensure optimal performance and protection even in extreme thermal conditions.

Temperature Limits Of Powder Coating

Exploring The Temperature Resistance Of Powder Coating

Powder coating is a popular method used to protect and enhance the appearance of various objects, from metal furniture to car parts. One of the key advantages of powder coating is its strong resistance to high temperatures. Understanding the temperature limits of powder coating is essential for ensuring its long-lasting durability and performance.

Let’s dive into the fascinating world of temperature resistance and explore what makes powder coating withstand even the harshest conditions.

Factors That Affect The Temperature Resistance Of Powder Coating

While powder coating is known for its exceptional resistance to heat, there are several factors that can influence its ability to withstand high temperatures. By considering these factors, you can ensure that your powder-coated surfaces remain intact and visually appealing, even under extreme thermal conditions.

1. Powder Coating Formulation

The formulation of the powder coating plays a crucial role in determining its temperature resistance. Different types of powder coatings have varying capabilities when it comes to withstanding heat. In general, epoxy-based and polyester-based powder coatings have excellent temperature resistance, making them suitable for applications that involve exposure to elevated temperatures.

2. Curing Process

The curing process is an essential step in powder coating application that significantly impacts its temperature resistance. The curing process involves heating the coated object to a specific temperature, allowing the powder particles to melt and form a durable, protective coating. Proper curing ensures that the powder coating maintains its integrity and can withstand high temperatures without cracking or peeling.

3. Substrate Material

The material of the substrate, or the surface being coated, also influences the temperature resistance of powder coating. Different materials have different thermal expansion and contraction rates, which can affect the adhesion and performance of the powder coating at high temperatures. For instance, metals like steel and aluminum generally have good heat conductivity, making them conducive to powder coating applications requiring temperature resistance.

4. Thickness Of The Coating

The thickness of the powder coating layer can impact its ability to withstand extreme temperatures. A thicker coating typically provides better heat insulation and protection for the underlying substrate. It is important to maintain a uniform coating thickness, as excessive thickness can lead to poor adhesion and compromised performance.

5. Operating Conditions

The actual operating conditions to which the powder-coated object will be exposed will determine its temperature resistance requirements. Factors such as the maximum temperature, duration of exposure, and any additional stressors like UV radiation or chemicals should be considered when selecting a powder coating and assessing its suitability for specific applications.

By considering these factors and choosing the appropriate powder coating formulation, ensuring proper curing, considering the substrate material, optimizing coating thickness, and accounting for operating conditions, you can ensure that your powder-coated surfaces remain resilient and resistant to high temperatures.

How High Can Powder Coating Withstand?

When it comes to the durability of powder coating, high temperature resistance is crucial. Powder coating is known for its ability to withstand extreme temperatures, making it a popular choice for a wide range of applications. From automotive parts to industrial equipment, powder coatings provide excellent protection against heat, ensuring longevity and performance.

Maximum Temperature Limits Of Powder Coating

Powder coating is designed to withstand a variety of temperatures, depending on the formulation and the specific application. The maximum temperature limit generally varies between 350°F (177°C) and 1000°F (537°C). Beyond these limits, the powder coating may start to lose its properties and may even become discolored or damaged.

It is important to note that different types of powder coatings have different temperature limits. Polyester powder coatings, for example, usually have a lower maximum temperature limit of around 350°F (177°C). On the other hand, high-temp powder coatings can withstand higher temperatures, up to 1000°F (537°C) or even higher.

To determine the maximum temperature limit of a specific powder coating, it is recommended to consult the manufacturer’s technical data sheet. This information will provide detailed specifications and guidelines regarding the temperature resistance of the powder coating.

Applications Where High Temperature Resistance Is Crucial

High temperature resistance is of utmost importance in various industries and applications. Here are a few examples where powder coatings with excellent heat resistance are crucial:

Automotive industry: Powder-coated exhaust systems, engine components, and other parts exposed to high temperatures require coatings that can withstand the heat generated.

Appliances and household items: Oven racks, stovetop burners, and other heat-generating appliances are commonly powder coated to provide heat resistance and protection from discoloration or damage.

Industrial equipment: Furnaces, heat exchangers, and other industrial equipment subjected to extreme temperatures rely on powder coatings for corrosion protection and heat resistance.

Outdoor furniture and structures: Powder-coated outdoor furniture, grills, and architectural structures need to withstand both environmental conditions and high temperatures.

These are just a few examples of the many applications where powder coatings with high temperature resistance play a vital role in maintaining functionality and aesthetics.

In conclusion, powder coatings can withstand high temperatures, making them suitable for a wide range of applications in various industries. Understanding the maximum temperature limits of different types of powder coatings ensures their proper usage and performance in extreme heat environments.

Industrial Applications

In the realm of industrial applications, powder coating has gained immense popularity due to its durability and cost-effectiveness. It offers a protective layer that can withstand extreme temperature variations, making it ideal for various industrial sectors such as automotive, aerospace, and machinery. Let’s dive deeper into how powder coating is used in these specific industries.

Powder Coating In Automotive And Aerospace Industries

In the fast-paced world of automotive and aerospace, the demand for high-performance coatings is paramount. Powder coating emerges as a preferred choice due to its ability to withstand tough conditions, including temperature fluctuations. Its exceptional resilience ensures that vehicles and aircraft are protected against rust, corrosion, and adverse weather conditions.

When it comes to the automotive industry, powder coating is widely employed in various applications including:

Exterior vehicle parts: Powder coating provides a robust shield for automotive exteriors, protecting them from harsh weather elements and ensuring an attractive finish.

Engine components: The intense heat generated by engines necessitates coatings that can endure extreme temperatures. Powder coating excels in this field, delivering outstanding heat resistance and increasing the lifespan of engine parts.

Wheels: Powder coated wheels boast enhanced durability, corrosion resistance, and a pleasing aesthetic appeal. They can handle both the scorching heat of the asphalt and the erratic weather conditions that vehicles encounter.

Aerospace, being an industry that operates in extreme conditions, relies on powder coating for its range of benefits:

Aircraft exteriors: Powder coating acts as a sturdy barrier against the harsh ultraviolet (UV) rays, high altitudes, and rapidly changing temperatures aircraft face during flights.

Engine parts: Similar to the automotive sector, powder coating is valuable in aerospace for protecting engine components from extreme heat generated during flight operations.

Interior fittings: Powder coating ensures resistance to wear and tear, enhances fire resistance, and prevents corrosion in various interior components of aircraft, thereby extending their lifespan.

Powder Coating For Industrial Machinery And Equipment

Industrial machinery and equipment often operate under harsh conditions, such as intense heat and exposure to chemicals. Powder coating serves as a reliable coating solution, effectively safeguarding these crucial assets. Here are some significant applications of powder coating in this sector:

Heavy machinery: Powder coating provides durable protection for machinery exposed to rough environments, including construction equipment, farming machinery, and mining tools. It acts as a tough barrier against corrosion, abrasion, and impact damage.

Pipelines and storage tanks: Powder coating is utilized to safeguard pipelines and storage tanks against rust, chemicals, and extreme temperature fluctuations. It ensures their longevity, even when operating in aggressive industrial environments.

Electronics and electrical equipment: Powder coating is commonly used for electrical enclosures, control panels, and other electronic components. Besides offering excellent resistance to temperature changes, it protects against moisture, UV radiation, and other external factors that can disrupt electrical systems.

With the versatility and durability of powder coating, the industrial machinery and equipment sector can achieve enhanced performance, reduced maintenance costs, and prolonged equipment life.

Home Applications

When it comes to enhancing the durability and appearance of various items in your home, powder coating is an excellent choice. This advanced finishing technique involves the application of a dry powder to a surface, which is then cured by heat, forming a protective and attractive coating.

Powder coating is known for its ability to withstand extreme temperatures, making it ideal for various home applications. Let’s explore how powder coating can be used to enhance the longevity and aesthetics of outdoor furniture, barbecue grills, kitchen appliances, and fixtures.

Powder Coating For Outdoor Furniture And Barbecue Grills

Outdoor furniture and barbecue grills are exposed to harsh weather conditions and high temperatures. To ensure they can withstand outdoor elements, powder coating offers reliable protection. Powder coating can withstand temperatures ranging from 300°F to 800°F, making it perfect for outdoor use.

This durable coating forms a barrier against corrosion, UV rays, and moisture, preventing rust and fading. Whether you have metal patio furniture or a stainless steel grill, powder coating ensures long-lasting performance and an eye-catching finish.

Powder Coating For Kitchen Appliances And Fixtures

In the heart of your home, your kitchen appliances and fixtures experience frequent exposure to heat and humidity. Powder coating provides a resilient solution for kitchen items, ensuring they can endure these challenging conditions without compromising their appearance or functionality. With the ability to withstand temperatures of up to 400°F, powder coating keeps your appliances and fixtures looking as good as new.

From refrigerators and ovens to sink faucets and cabinet handles, powder coating transforms the surfaces, making them resistant to scratches, stains, and fading. This protective layer not only enhances the longevity of your kitchen items but also adds a touch of elegance to the overall aesthetics of your space.

Frequently Asked Questions For What Temperature Can Powder Coating Withstand?

What Temperature Does Powder Coat Burn Off?

Powder coat burns off at temperatures typically ranging between 400 to 450 degrees Fahrenheit.

Will Powder Coat Cure At 200 Degrees?

Yes, powder coat will cure at 200 degrees.

Is There A Heat Resistant Powder Coating?

Yes, there are heat resistant powder coatings available. These coatings are designed to withstand high temperatures and provide protection for various surfaces. They are a durable option for items exposed to heat, such as automotive parts, grills, and industrial equipment.

How Cold Can Powder Coating Withstand?

Powder coating can withstand extremely cold temperatures. It is designed to remain stable and durable in subzero conditions.

Conclusion

Powder coating is a durable and versatile finishing option for various materials, offering excellent resistance against high temperatures. Withstanding temperatures of up to 1000°F, it provides long-lasting protection and aesthetic appeal. Whether preparing automotive parts or outdoor furniture, powder coating ensures superior performance and durability in demanding environments.

So, consider powder coating as a reliable solution for your next project.